Microelectromechanical Systems

Group of 2, January 2016 - March 2016

Fabrication & characterization: Garman Chan

Fabrication & characterization: Me

The Microelectromechanical Systems course covered the theory and practice of designing and fabricating MEMS devices including understanding the fundamentals of photolithography, BOE, microfluidics, and capacitive sensors.

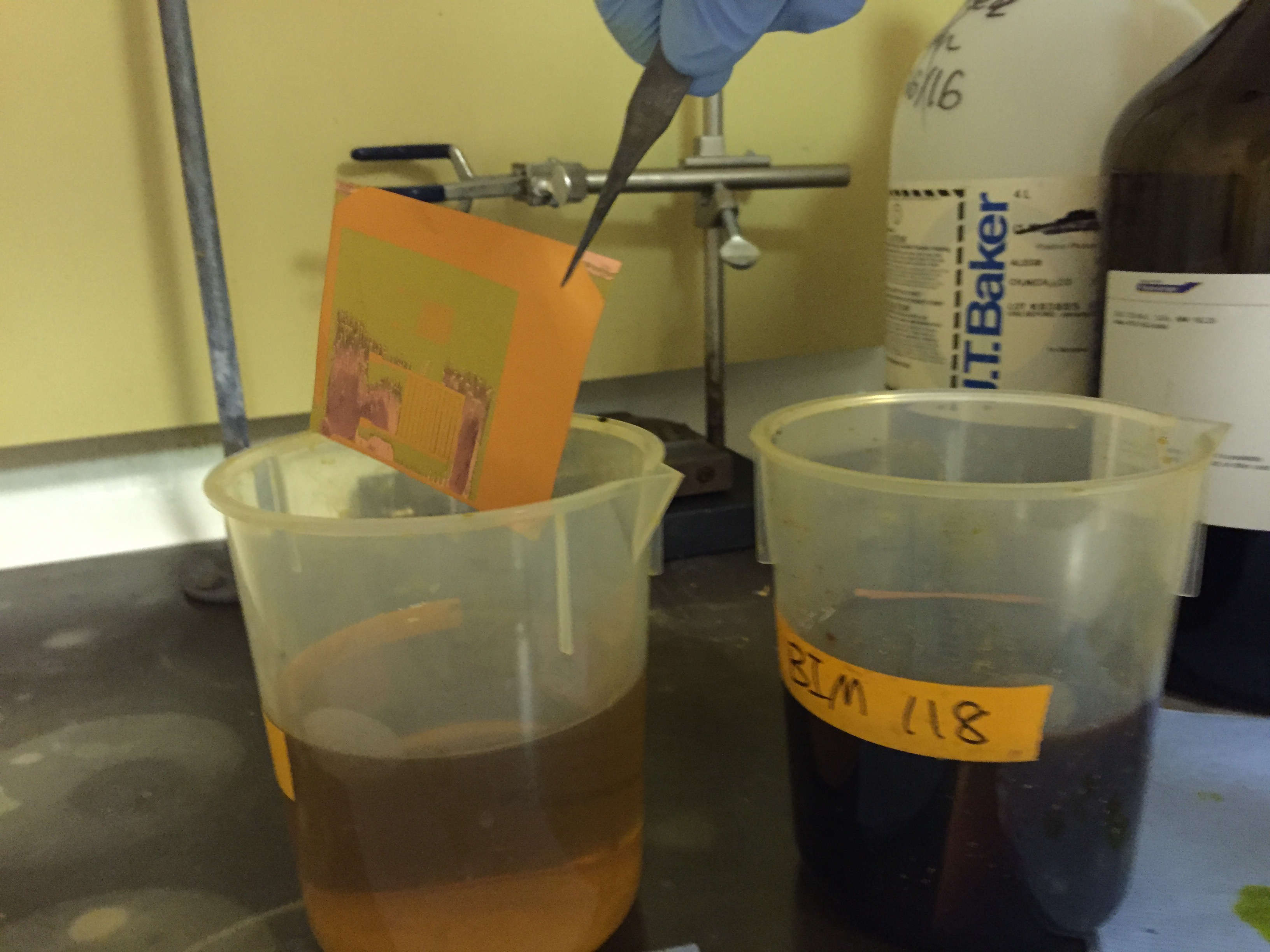

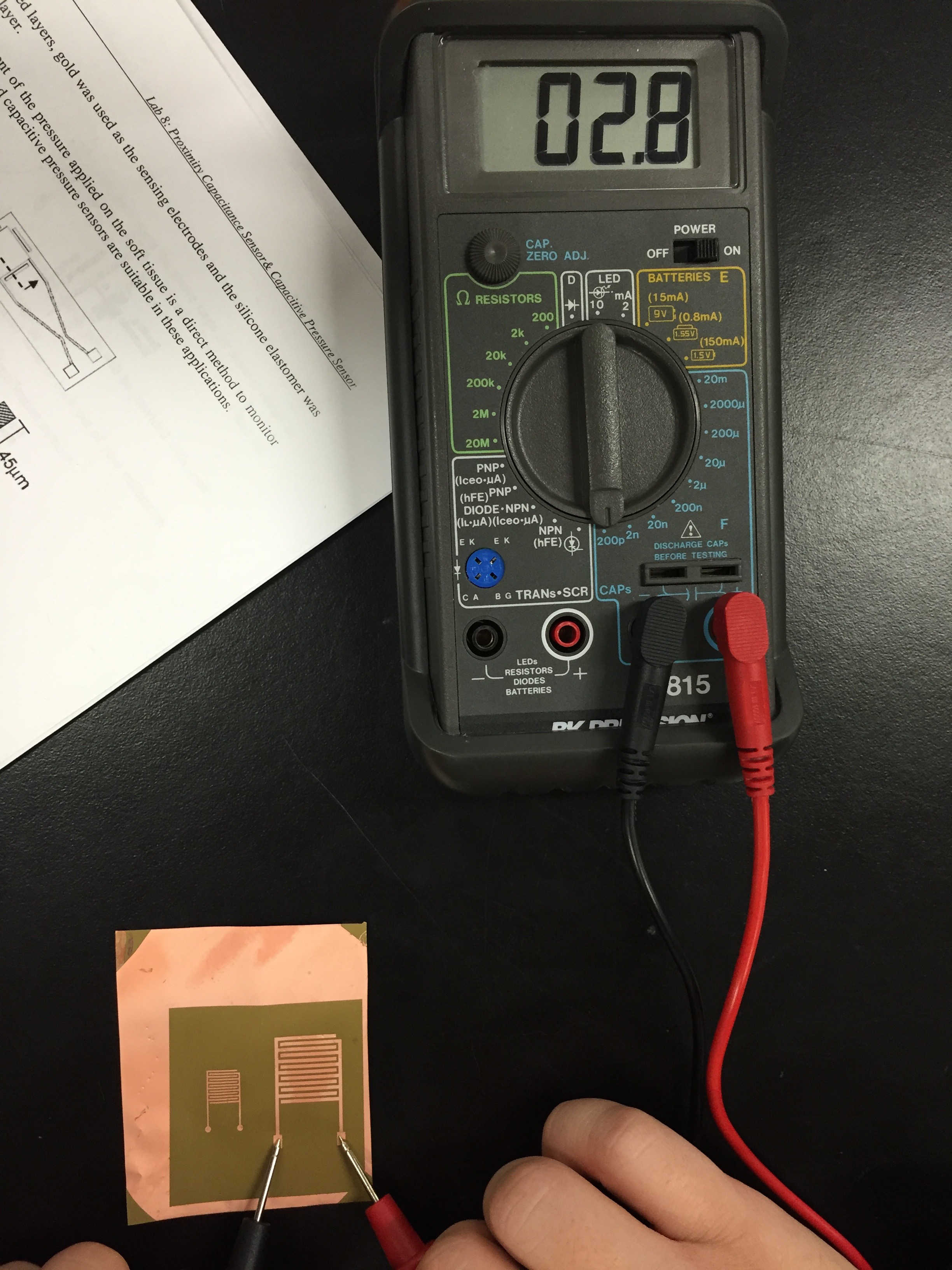

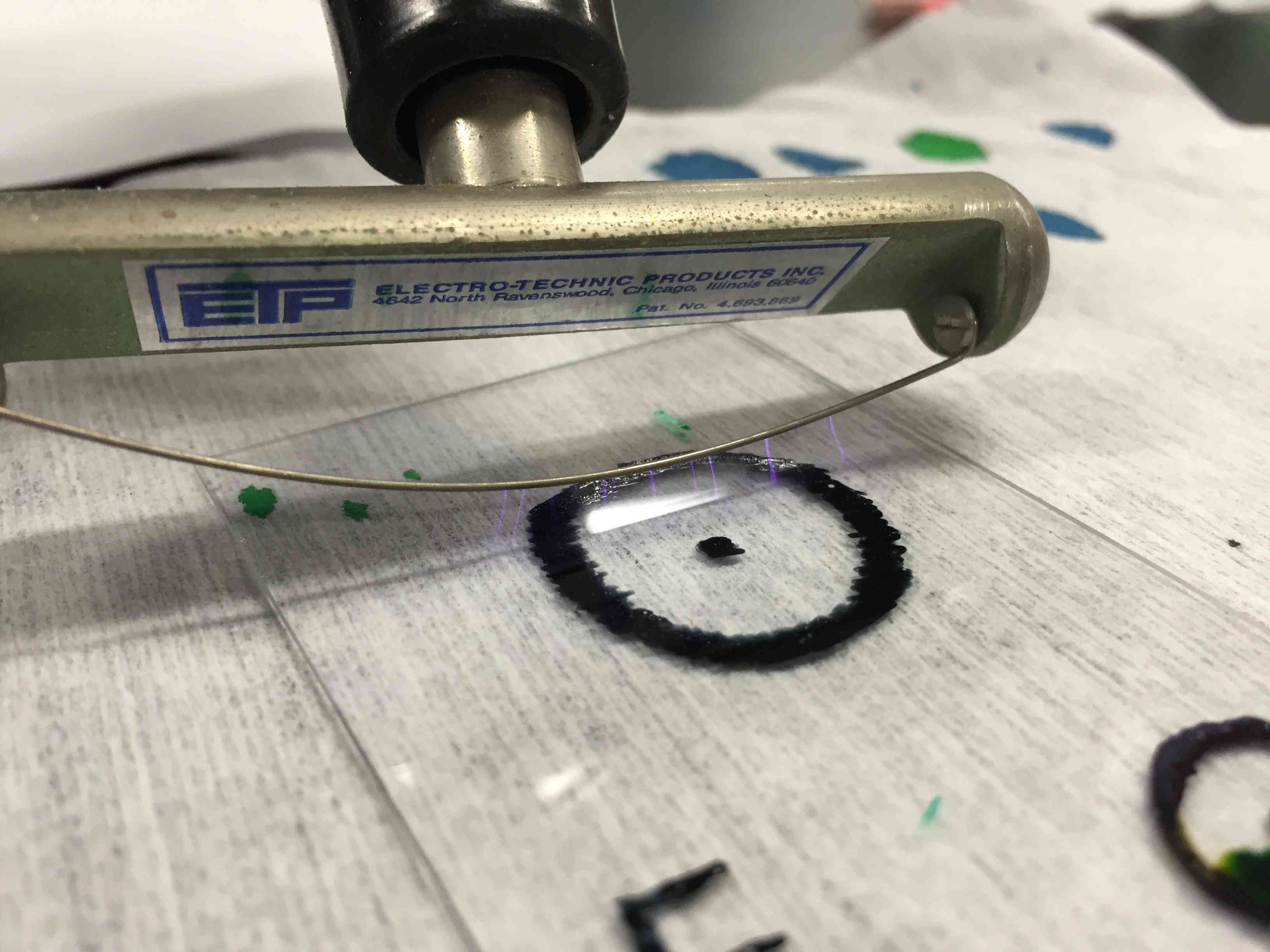

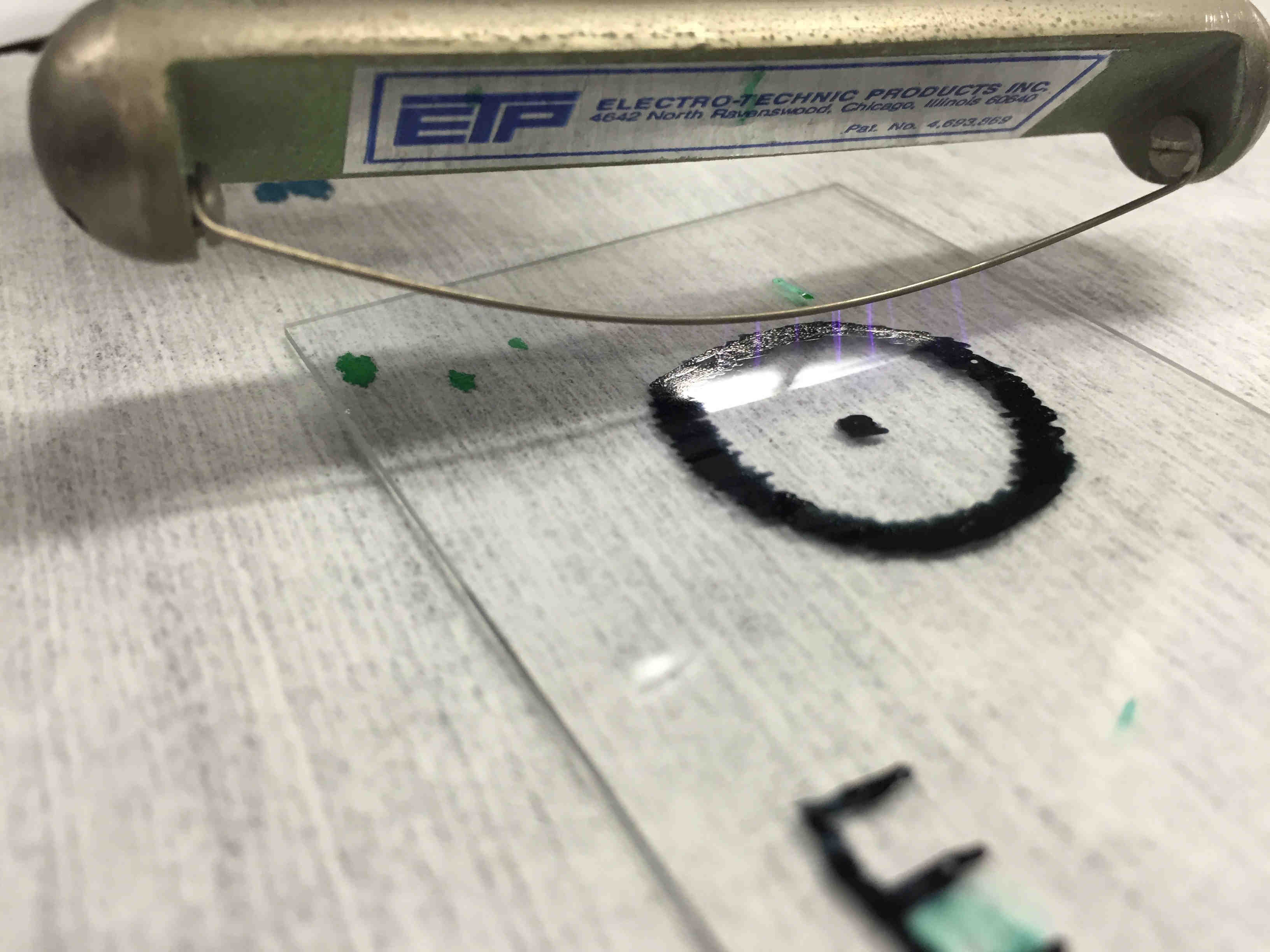

The labs were conducted in the university class 100 cleanroom and the biological science department's laboratories. We deigned one capacitive sensor for touch, and another for larger forces, and both on copper electrodes. The pictures show etching of the electrode after photolithography was used to pattern it. The sensors were then characterized using a voltmeter.

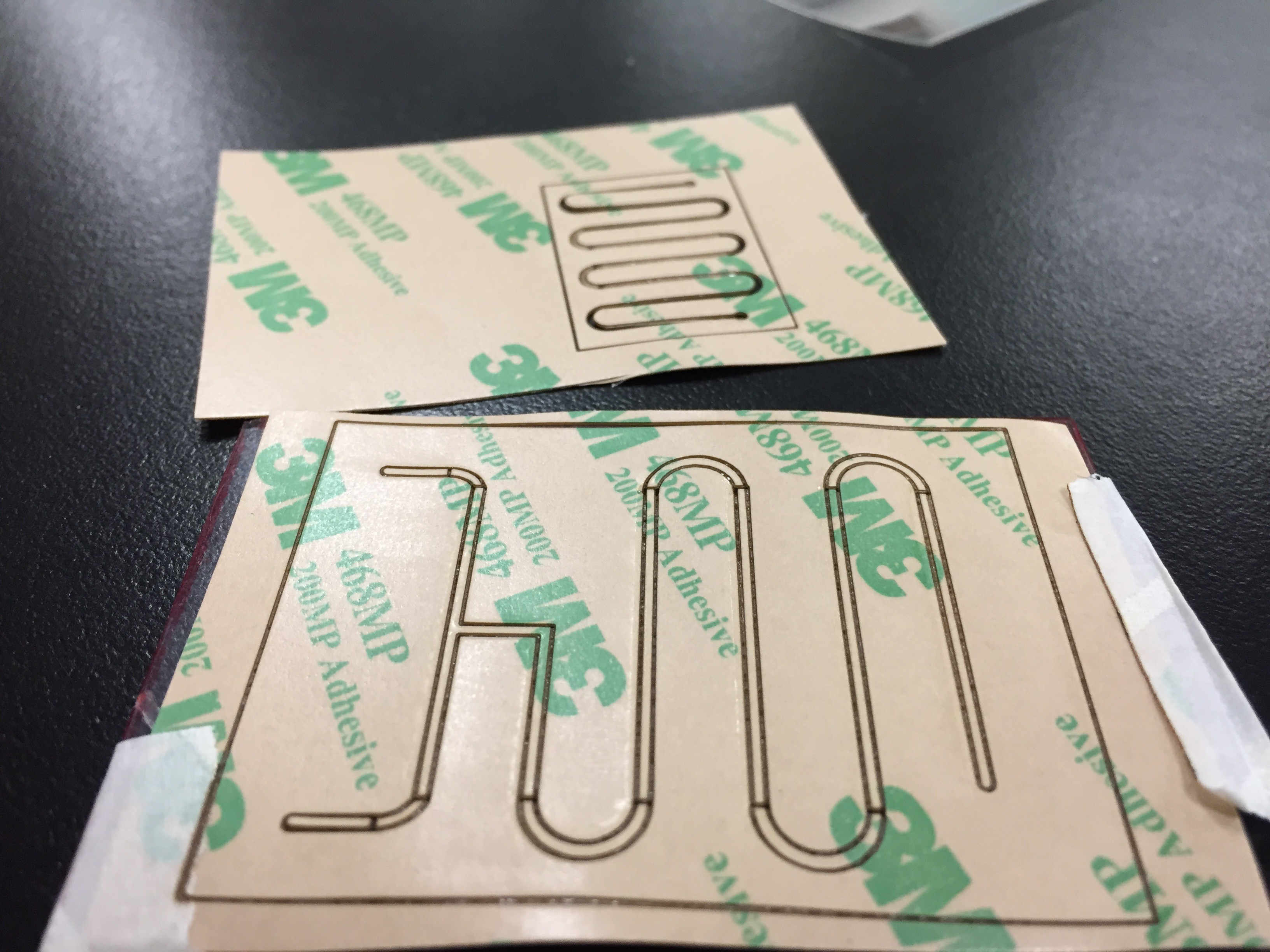

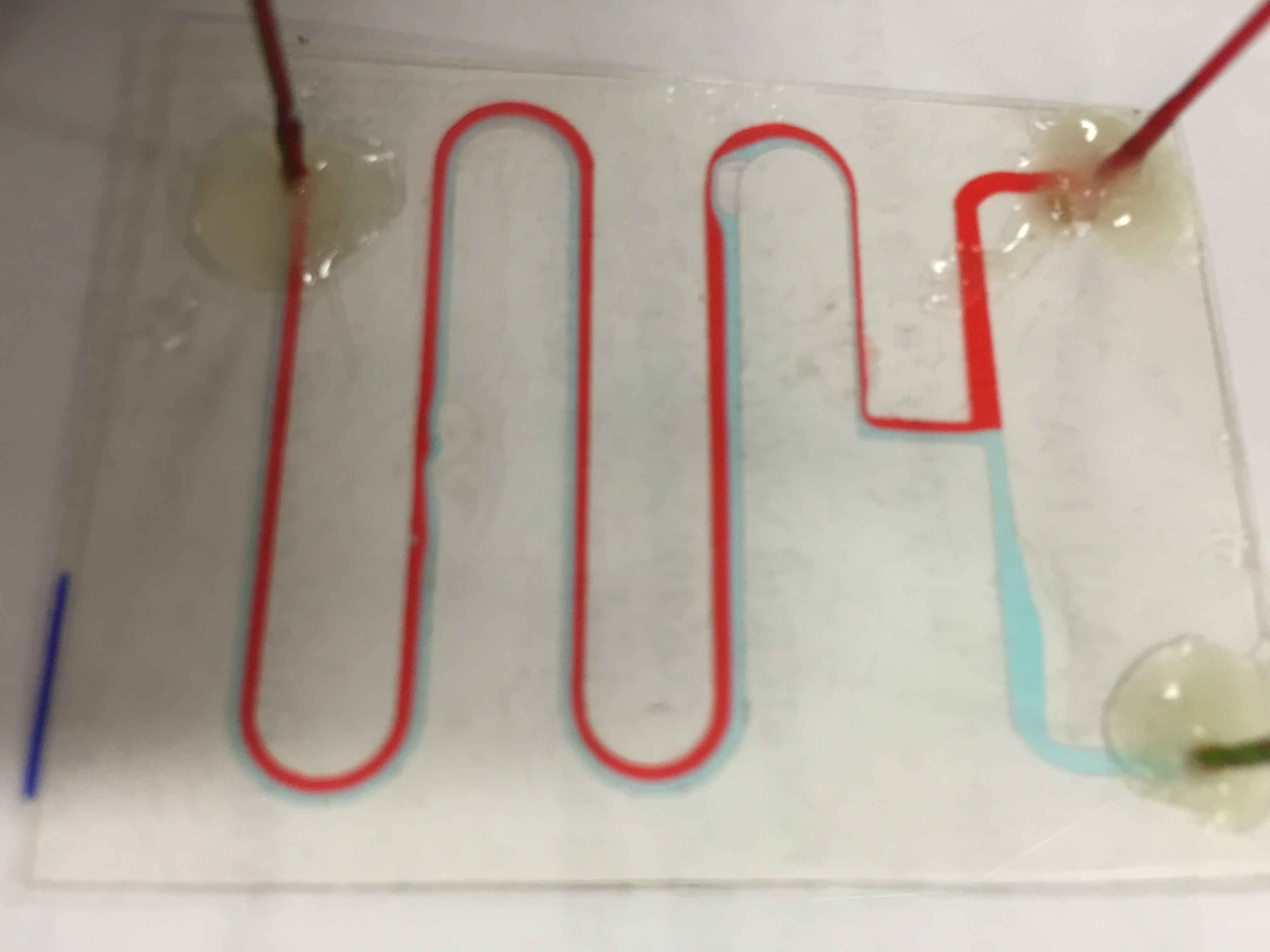

A micro fluid lab on chip device was designed and fabricated to characterize two fluids. A laser was used to cut different layers of adhesive that combined to create the substrate. Different fluids were piped through the device so the flow rate, and density could be calculated.

Additionally we cleaned glass surfaces with a Corona Discharge and observed the short and long range interaction of micro fluid droplets. Long range they are drawn together because of a gradient surface tension described by the Marangoni effect. Short range the droplets displayed merge, broken chase, intact chase, and tendril, based on surface tension gradients that changed based on the concentration of food coloring used in each drop.